What sets TU bearings apart is their ingenious self-lubricating property. Crafted from a composite material, these bearings incorporate solid lubricants within their structure. As machinery operates, a thin film of lubricant is continuously released onto the bearing surface, ensuring smooth and frictionless motion. Say goodbye to constant greasing or oiling, as TU bearings reduce wear, heat, and energy consumption, while extending the life of your equipment. Our bearings are comparable to the commercially available DU bearing, SF bearings or Glycodur bearings.

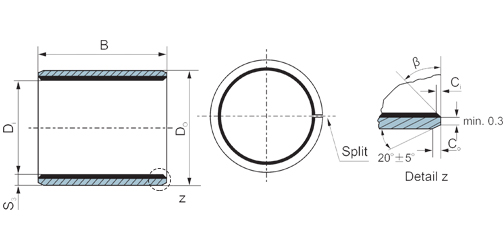

| S3 | CO | Ci | β |

|---|---|---|---|

| 0.75 | 0.5±0.3 | 0.25±0.2 | 35°±5° |

| 1.00 | 0.6±0.3 | 0.30±0.2 | 35°±5° |

| 1.50 | 0.7±0.3 | 0.50±0.3 | 35°±5° |

| S3 | CO | Ci | β |

|---|---|---|---|

| 2.00 | 1.2±0.4 | 0.50±0.3 | 35°±5° |

| 2.00 | 1.8±0.6 | 0.60±0.3 | 45°±5° |

| Unit : mm | |||

| Operating Performance | |

|---|---|

| Dry | Good |

| Oil lubricated | Very Good |

| Grease lubricated | Good |

| Water lubricated | Fair |

| Process fluid lubricated | Good |

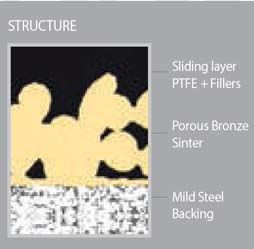

| Structure of the material: | ||

|---|---|---|

| Layer | Average analysis of the material | Thickness of layer |

| Sliding layer (Minimum) |

PTFE Coating | 10 - 30μm |

| Intermediate layer (Average Peak) |

CuSn11 Sintered | 200÷350μm |

| Supporting shell | Mild Steel (Also tin/zinc coated) |

0,70 ÷ 2,20 mm (Depending on Dim. of the Bearing) |

| TECHNICAL DATA | ||||||

|---|---|---|---|---|---|---|

| Max. load | Static | 250N/mm2 | Temp. limit | -195°c ~ +280°c | ||

| Very low speed | 140N/mm2 | Max. speed | Dry running | 2 m/s | ||

| Rotating oscillating | 60N/mm2 | Hydrodynamic operation | >2 m/s | |||

| Max. PV dry running | Short-term operation | 3.6N/mm2*m/s | Thermal conductivity | 42W(m*K)-1 | ||

| Continuous operation | 1.8N/mm2*m/s | Coefficient of thermal expansion | 11*10-6*K-1 | |||

| PV max. hydrodynamic | 30N/mm2*m/s | Friction coefficien | Dry | 0.08 ~ 0.20 | ||

| Hydrodynamic | 0.03 ~ 0.08 | |||||

Good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Very good performance in lubricated applications

Good performance in greased applications

Suitable for linear, oscillating and rotating movements

Lead-free material

Standard forms in special dimensions, half-bearings, special shapes obtained by stamping or deep drawing, bearings with locating notches, lubricant holes and machined/stamped grooves, customized bearing designs

Automotive Aerospace, agricultural equipment, construction equipment, pumps and motors, railroad and tramways, textile machinery, valves, food and beverage, material handling equipment, forming machines: metal, plastic and rubber; office equipment, medical and scientific equipment, packaging equipment, pneumatic and hydraulic cylinders.

| AXLE | HOUSING H7 | OD Tolerance | ID After fixing | Wall thickness | L0-0.40 (d ≤ 30 L - 0.3d ≥ 30 L - 0.4) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | 40 | 50 | |||||

| 6-0.013-0.028 | 8+0.015 | 8+0.055+0.025 | 6.055 5.990 |

1.005 0.980 |

0606 | 0608 | 0610 | |||||||

| 8-0.013-0.028 | 10+0.015 | 10+0.055+0.025 | 8.055 7.990 |

0806 | 0808 | 0810 | 0812 | 0815 | ||||||

| 10-0.013-0.028 | 12+0.018 | 12+0.065+0.030 | 10.058 9.990 |

1006 | 1008 | 1010 | 1012 | 1015 | 1020 | |||||

| 12-0.016-0.034 | 14+0.018 | 14+0.065+0.030 | 12.058 11.990 |

1206 | 1208 | 1210 | 1212 | 1215 | 1220 | 1225 | ||||

| 13-0.016-0.034 | 15+0.018 | 15+0.065+0.030 | 13.058 12.990 |

1310 | 1320 | |||||||||

| 14-0.016-0.034 | 16+0.018 | 16+0.065+0.030 | 14.058 13.990 |

1410 | 1412 | 1415 | 1420 | 1425 | ||||||

| 15-0.016-0.034 | 17+0.018 | 17+0.065+0.030 | 15.058 14.990 |

1510 | 1512 | 1515 | 1520 | 1525 | ||||||

| 16-0.016-0.034 | 18+0.018 | 18+0.065+0.030 | 16.058 15.990 |

1610 | 1612 | 1615 | 1620 | 1625 | ||||||

| 17-0.016-0.034 | 19+0.021 | 19+0.075+0.035 | 17.061 16.990 |

1.505 1.475 |

1710 | 1712 | 1720 | |||||||

| 18-0.016-0.034 | 20+0.021 | 20+0.075+0.035 | 18.061 17.990 |

1810 | 1812 | 1815 | 1820 | 1825 | ||||||

| 20-0.020-0.041 | 23+0.021 | 23+0.075+0.035 | 20.071 19.990 |

2010 | 2012 | 2015 | 2020 | 2025 | 2030 | |||||

| 22-0.020-0.041 | 25+0.021 | 25+0.075+0.035 | 22.071 21.990 |

2210 | 2212 | 2215 | 2220 | 2225 | 2230 | |||||

| 24-0.020-0.041 | 27+0.021 | 27+0.075+0.035 | 24.071 23.990 |

2415 | 2420 | 2425 | 2430 | |||||||

| 25-0.020-0.041 | 28+0.021 | 28+0.075+0.035 | 25.071 24.990 |

2510 | 2512 | 2515 | 2520 | 2525 | 2530 | 2540 | 2550 | |||

| 28-0.020-0.041 | 32+0.021 | 32+0.085+0.045 | 28.085 27.990 |

2.005 1.970 |

2815 | 2820 | 2825 | 2830 | 2840 | |||||

| 30-0.020-0.041 | 34+0.025 | 34+0.085+0.045 | 30.085 29.990 |

3012 | 3015 | 3020 | 3025 | 3030 | 3040 | |||||

| 32-0.025-0.050 | 36+0.025 | 36+0.085+0.045 | 32.085 31.990 |

3220 | 3230 | 3240 | ||||||||

| 35-0.025-0.050 | 39+0.025 | 39+0.085+0.045 | 35.085 34.990 |

3512 | 3515 | 3520 | 3525 | 3530 | 3540 | 3550 | ||||

| 38-0.025-0.050 | 42+0.025 | 42+0.085+0.045 | 38.085 37.990 |

3815 | 3830 | 3840 | ||||||||

| 40-0.025-0.050 | 44+0.025 | 44+0.085+0.045 | 40.085 39.990 |

4012 | 4020 | 4025 | 4030 | 4040 | 4050 | |||||

| 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 100 | 115 | |||||

| 45-0.025-0.050 | 50+0.025 | 50+0.085+0.045 | 45.105 44.990 |

2.505 2.460 |

4520 | 4525 | 4530 | 4540 | 4550 | |||||

| 50-0.025-0.050 | 55+0.030 | 55+0.100+0.055 | 50.110 49.990 |

5020 | 5030 | 5040 | 5050 | 5060 | ||||||

| 55-0.030-0.060 | 60+0.030 | 60+0.100+0.055 | 55.110 54.990 |

5530 | 5540 | 5550 | 5560 | |||||||

| 60-0.030-0.060 | 65+0.030 | 65+0.100+0.055 | 60.110 59.990 |

6030 | 6040 | 6050 | 6060 | 6070 | ||||||

| 65-0.030-0.060 | 70+0.030 | 70+0.100+0.055 | 65.110 64.990 |

6530 | 6540 | 6550 | 6560 | 6570 | ||||||

| 70-0.030-0.060 | 75+0.030 | 75+0.100+0.055 | 70.110 69.990 |

7040 | 7050 | 7060 | 7070 | 7080 | ||||||

| 75-0.030-0.060 | 80+0.030 | 80+0.100+0.055 | 75.110 74.990 |

7530 | 7540 | 7550 | 7560 | 7570 | 7580 | |||||

| 80-0.030 | 85+0.035 | 85+0.120+0.070 | 80.155 80.020 |

2.490 2.440 |

8040 | 8050 | 8060 | 8070 | 8080 | 80100 | ||||

| 85-0.035 | 90+0.035 | 90+0.120+0.070 | 85.155 85.020 |

8540 | 8560 | 8580 | 85100 | |||||||

| 90-0.035 | 95+0.035 | 95+0.120+0.070 | 90.155 90.020 |

9040 | 9050 | 9060 | 9080 | 90100 | ||||||

| 95-0.035 | 100+0.035 | 100+0.120+0.070 | 95.155 95.020 |

9550 | 9560 | 9580 | 95100 | |||||||

| 100-0.035 | 105+0.035 | 105+0.120+0.070 | 100.155 100.020 |

10050 | 10060 | 10080 | 100115 | |||||||

| 105-0.035 | 110+0.035 | 110+0.120+0.070 | 105.155 105.020 |

10560 | 10580 | 105115 | ||||||||

| 110-0.035 | 115+0.035 | 115+0.120+0.070 | 110.155 110.020 |

11060 | 11080 | 110115 | ||||||||

| 120-0.035 | 125+0.040 | 125+0.170+0.100 | 120.210 120.070 |

2.465 2.415 |

12060 | 12080 | 120100 | |||||||

| 125-0.035 | 130+0.040 | 130+0.170+0.100 | 125.210 125.070 |

12560 | 125100 | 125115 | ||||||||

| 130-0.040 | 135+0.040 | 135+0.170+0.100 | 130.210 130.070 |

13060 | 13080 | 130100 | ||||||||

| 140-0.040 | 145+0.040 | 145+0.170+0.100 | 140.210 140.070 |

14060 | 14080 | 140100 | ||||||||

| 150-0.040 | 155+0.040 | 155+0.170+0.100 | 150.210 150.070 |

15060 | 15080 | 150100 | ||||||||

| 160-0.040 | 165+0.040 | 165+0.170+0.100 | 160.210 160.070 |

16060 | 16080 | 160100 | 160115 | |||||||

| 180-0.040 | 185+0.046 | 185+0.210+0.130 | 180.216 180.070 |

2.465 2.415 |

18080 | 180100 | ||||||||

| 190-0.046 | 195+0.046 | 195+0.210+0.130 | 190.216 190.070 |

19080 | 190100 | |||||||||

| 200-0.046 | 205+0.046 | 205+0.210+0.130 | 200.216 200.070 |

20060 | 20080 | 200100 | ||||||||

| 220-0.046 | 225+0.046 | 225+0.210+0.130 | 220.216 220.070 |

22080 | 220100 | |||||||||

| 250-0.046 | 255+0.052 | 255+0.260+0.170 | 250.222 250.070 |

25080 | 250100 | |||||||||

| 260-0.052 | 265+0.052 | 265+0.260+0.170 | 260.222 260.070 |

2.465 2.415 |

26080 | 260100 | ||||||||

| 280-0.052 | 285+0.052 | 285+0.210+0.130 | 280.222 280.070 |

28080 | 280100 | |||||||||

| 300-0.052 | 305+0.052 | 305+0.210+0.130 | 300.222 300.070 |

30080 | 300100 | |||||||||