DX bearings are cutting-edge composite bearings designed to deliver exceptional performance in various applications. These bearings combine the advantages of different materials, offering a winning combination of strength, self-lubrication, and versatility. Whether you need bearings for heavy industrial machinery, automotive components, or marine equipment, DX bearings are engineered to excel. These bushes are marginally lubricated, they have pockets to retain grease or oil during operation.

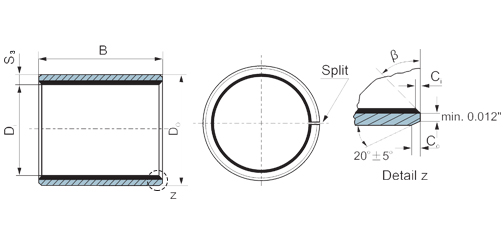

| S3 | CO | Ci | β |

|---|---|---|---|

| 0.0315 | 0.008-0.030 | 0.002-0.018 | 30°±5° |

| 0.0472 | 0.012-0.035 | 0.006-0.022 | 30°±5° |

| 0.0630 | 0.015-0.040 | 0.008-0.032 | 30°±5° |

| S3 | CO | Ci | β |

|---|---|---|---|

| 0.0787 | 0.030-0.060 | 0.008-0.032 | 30°±5° |

| 0.0945 | 0.050-0.095 | 0.020-0.043 | 45°±5° |

| Unit : mm | |||

| Operating Performance | |

|---|---|

| Dry | Poor |

| Oil lubricated | Good |

| Grease lubricated | Very Good |

| Water lubricated | Poor |

| Process fluid lubricated | Poor |

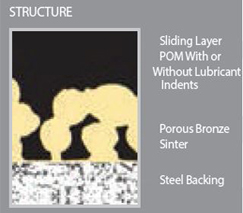

| Structure of the material: | ||

|---|---|---|

| Layer | Average analysis of the material | Thickness of layer |

| Sliding layer (Minimum) |

POM-C | 250 - 450 μm |

| Intermediate layer (Average Peak) |

CuSn11 Sintered | 200 - 350μm |

| Supporting shell | Low Carbon Steel | 0,50 ÷ 2,70 mm (Depending on Dim. of the Bearing) |

| Protective layer | Sn or Zn | 2 - 8 μm |

| TECHNICAL DATA | ||||||

|---|---|---|---|---|---|---|

| Max. load | Static | 140N/mm2 | Temp. limit | -30°c to +130°c | ||

| Very low speed | 70N/mm2 | Max. speed | Dry running | 2.5 m/s | ||

| Rotating oscillating | 60N/mm2 | Hydrodynamic operation | >2.5 m/s | |||

| Max. PV dry running | Short-term operation | 3.6N/mm2*m/s | Thermal conductivity | 42W(m*K)-1 | ||

| Continuous operation | 2.8N/mm2*m/s | Coefficient of thermal expansion | 11*10-6*K-1 | |||

| PV max. hydrodynamic | 30N/mm2*m/s | Friction coefficient | Dry | 0.06 ~ 0.12 | ||

| Hydrodynamic | 0.03 ~ 0.08 | |||||

Marginally lubricated bearing material for grease or oil lubricated applications

Standard parts contain grease indents in the sliding layer; plain sliding layer available by request

Optimum performance under relatively high loads and low speeds

Suitable for linear, oscillating and rotating movements

Wide range of parts available from stock

Standard forms in special dimensions, half-bearings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bearing designs.

Automotive Mechanical handling and lifting equipment, machine slides, hydraulic cylinders, hydraulic motors, ski-lifts, pneumatic equipment, medical equipment, textile machinery, agricultural equipment, scientific equipment etc.

| AXLE | HOUSING H7 | OD Tolerance | ID After fixing | Wall thickness | L0-0.40 (d ≤ 30 L - 0.3d ≥ 30 L - 0.4) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | 40 | 50 | |||||

| 6-0.013-0.028 | 8+0.015 | 8+0.055+0.025 | 6.055 5.990 |

1.005 0.980 |

0606 | 0608 | 0610 | |||||||

| 8-0.013-0.028 | 10+0.015 | 10+0.055+0.025 | 8.055 7.990 |

0806 | 0808 | 0810 | 0812 | 0815 | ||||||

| 10-0.013-0.028 | 12+0.018 | 12+0.065+0.030 | 10.058 9.990 |

1006 | 1008 | 1010 | 1012 | 1015 | 1020 | |||||

| 12-0.016-0.034 | 14+0.018 | 14+0.065+0.030 | 12.058 11.990 |

1206 | 1208 | 1210 | 1212 | 1215 | 1220 | 1225 | ||||

| 13-0.016-0.034 | 15+0.018 | 15+0.065+0.030 | 13.058 12.990 |

1310 | 1320 | |||||||||

| 14-0.016-0.034 | 16+0.018 | 16+0.065+0.030 | 14.058 13.990 |

1410 | 1412 | 1415 | 1420 | 1425 | ||||||

| 15-0.016-0.034 | 17+0.018 | 17+0.065+0.030 | 15.058 14.990 |

1510 | 1512 | 1515 | 1520 | 1525 | ||||||

| 16-0.016-0.034 | 18+0.018 | 18+0.065+0.030 | 16.058 15.990 |

1610 | 1612 | 1615 | 1620 | 1625 | ||||||

| 17-0.016-0.034 | 19+0.021 | 19+0.075+0.035 | 17.061 16.990 |

1.505 1.475 |

1710 | 1712 | 1720 | |||||||

| 18-0.016-0.034 | 20+0.021 | 20+0.075+0.035 | 18.061 17.990 |

1810 | 1812 | 1815 | 1820 | 1825 | ||||||

| 20-0.020-0.041 | 23+0.021 | 23+0.075+0.035 | 20.071 19.990 |

2010 | 2012 | 2015 | 2020 | 2025 | 2030 | |||||

| 22-0.020-0.041 | 25+0.021 | 25+0.075+0.035 | 22.071 21.990 |

2210 | 2212 | 2215 | 2220 | 2225 | 2230 | |||||

| 24-0.020-0.041 | 27+0.021 | 27+0.075+0.035 | 24.071 23.990 |

2415 | 2420 | 2425 | 2430 | |||||||

| 25-0.020-0.041 | 28+0.021 | 28+0.075+0.035 | 25.071 24.990 |

2510 | 2512 | 2515 | 2520 | 2525 | 2530 | 2540 | 2550 | |||

| 28-0.020-0.041 | 32+0.021 | 32+0.085+0.045 | 28.085 27.990 |

2.005 1.970 |

2815 | 2820 | 2825 | 2830 | 2840 | |||||

| 30-0.020-0.041 | 34+0.025 | 34+0.085+0.045 | 30.085 29.990 |

3012 | 3015 | 3020 | 3025 | 3030 | 3040 | |||||

| 32-0.025-0.050 | 36+0.025 | 36+0.085+0.045 | 32.085 31.990 |

3220 | 3230 | 3240 | ||||||||

| 35-0.025-0.050 | 39+0.025 | 39+0.085+0.045 | 35.085 34.990 |

3512 | 3515 | 3520 | 3525 | 3530 | 3540 | 3550 | ||||

| 38-0.025-0.050 | 42+0.025 | 42+0.085+0.045 | 38.085 37.990 |

3815 | 3830 | 3840 | ||||||||

| 40-0.025-0.050 | 44+0.025 | 44+0.085+0.045 | 40.085 39.990 |

4012 | 4020 | 4025 | 4030 | 4040 | 4050 | |||||

| 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 100 | 115 | |||||

| 45-0.025-0.050 | 50+0.025 | 50+0.085+0.045 | 45.105 44.990 |

2.505 2.460 |

4520 | 4525 | 4530 | 4540 | 4550 | |||||

| 50-0.025-0.050 | 55+0.030 | 55+0.100+0.055 | 50.110 49.990 |

5020 | 5030 | 5040 | 5050 | 5060 | ||||||

| 55-0.030-0.060 | 60+0.030 | 60+0.100+0.055 | 55.110 54.990 |

5530 | 5540 | 5550 | 5560 | |||||||

| 60-0.030-0.060 | 65+0.030 | 65+0.100+0.055 | 60.110 59.990 |

6030 | 6040 | 6050 | 6060 | 6070 | ||||||

| 65-0.030-0.060 | 70+0.030 | 70+0.100+0.055 | 65.110 64.990 |

6530 | 6540 | 6550 | 6560 | 6570 | ||||||

| 70-0.030-0.060 | 75+0.030 | 75+0.100+0.055 | 70.110 69.990 |

7040 | 7050 | 7060 | 7070 | 7080 | ||||||

| 75-0.030-0.060 | 80+0.030 | 80+0.100+0.055 | 75.110 74.990 |

7530 | 7540 | 7550 | 7560 | 7570 | 7580 | |||||

| 80-0.030 | 85+0.035 | 85+0.120+0.070 | 80.155 80.020 |

2.490 2.440 |

8040 | 8050 | 8060 | 8070 | 8080 | 80100 | ||||

| 85-0.035 | 90+0.035 | 90+0.120+0.070 | 85.155 85.020 |

8540 | 8560 | 8580 | 85100 | |||||||

| 90-0.035 | 95+0.035 | 95+0.120+0.070 | 90.155 90.020 |

9040 | 9050 | 9060 | 9080 | 90100 | ||||||

| 95-0.035 | 100+0.035 | 100+0.120+0.070 | 95.155 95.020 |

9550 | 9560 | 9580 | 95100 | |||||||

| 100-0.035 | 105+0.035 | 105+0.120+0.070 | 100.155 100.020 |

10050 | 10060 | 10080 | 100115 | |||||||

| 105-0.035 | 110+0.035 | 110+0.120+0.070 | 105.155 105.020 |

10560 | 10580 | 105115 | ||||||||

| 110-0.035 | 115+0.035 | 115+0.120+0.070 | 110.155 110.020 |

11060 | 11080 | 110115 | ||||||||

| 120-0.035 | 125+0.040 | 125+0.170+0.100 | 120.210 120.070 |

2.465 2.415 |

12060 | 12080 | 120100 | |||||||

| 125-0.035 | 130+0.040 | 130+0.170+0.100 | 125.210 125.070 |

12560 | 125100 | 125115 | ||||||||

| 130-0.040 | 135+0.040 | 135+0.170+0.100 | 130.210 130.070 |

13060 | 13080 | 130100 | ||||||||

| 140-0.040 | 145+0.040 | 145+0.170+0.100 | 140.210 140.070 |

14060 | 14080 | 140100 | ||||||||

| 150-0.040 | 155+0.040 | 155+0.170+0.100 | 150.210 150.070 |

15060 | 15080 | 150100 | ||||||||

| 160-0.040 | 165+0.040 | 165+0.170+0.100 | 160.210 160.070 |

16060 | 16080 | 160100 | 160115 | |||||||

| 180-0.040 | 185+0.046 | 185+0.210+0.130 | 180.216 180.070 |

2.465 2.415 |

18080 | 180100 | ||||||||

| 190-0.046 | 195+0.046 | 195+0.210+0.130 | 190.216 190.070 |

19080 | 190100 | |||||||||

| 200-0.046 | 205+0.046 | 205+0.210+0.130 | 200.216 200.070 |

20060 | 20080 | 200100 | ||||||||

| 220-0.046 | 225+0.046 | 225+0.210+0.130 | 220.216 220.070 |

22080 | 220100 | |||||||||

| 250-0.046 | 255+0.052 | 255+0.260+0.170 | 250.222 250.070 |

25080 | 250100 | |||||||||

| 260-0.052 | 265+0.052 | 265+0.260+0.170 | 260.222 260.070 |

2.465 2.415 |

26080 | 260100 | ||||||||

| 280-0.052 | 285+0.052 | 285+0.210+0.130 | 280.222 280.070 |

28080 | 280100 | |||||||||

| 300-0.052 | 305+0.052 | 305+0.210+0.130 | 300.222 300.070 |

30080 | 300100 | |||||||||