Tin/zinc plating + mild steel + Porous bronze sinter + PTFE

Self lubricating and low maintenance

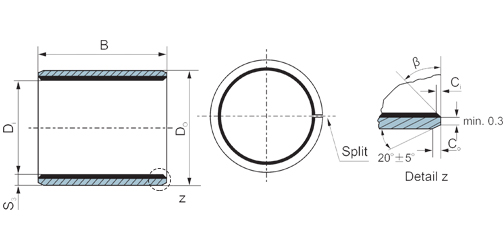

| S3 | CO | Ci | β |

|---|---|---|---|

| 0.75 | 0.5±0.3 | 0.25±0.2 | 35°±5° |

| 1.00 | 0.6±0.3 | 0.30±0.2 | 35°±5° |

| 1.50 | 0.7±0.3 | 0.50±0.3 | 35°±5° |

| S3 | CO | Ci | β |

|---|---|---|---|

| 2.00 | 1.2±0.4 | 0.50±0.3 | 35°±5° |

| 2.00 | 1.8±0.6 | 0.60±0.3 | 45°±5° |

| Unit : mm | |||

| Operating Performance | |

|---|---|

| Dry | Good |

| Oil lubricated | Very Good |

| Grease lubricated | Good |

| Water lubricated | Fair |

| Process fluid lubricated | Good |

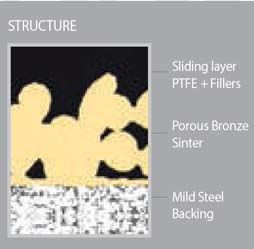

| Structure of the material: | ||

|---|---|---|

| Layer | Average analysis of the material | Thickness of layer |

| Sliding layer (Minimum) |

PTFE Coating | 10 - 30μm |

| Intermediate layer (Average Peak) |

CuSn11 Sintered | 200÷350μm |

| Supporting shell | Mild Steel (Also tin/zinc coated) |

0,70 ÷ 2,20 mm (Depending on Dim. of the Bearing) |

| TECHNICAL DATA | ||||||

|---|---|---|---|---|---|---|

| Max. load | Static | 250N/mm2 | Temp. limit | -195°c ~ +280°c | ||

| Very low speed | 140N/mm2 | Max. speed | Dry running | 2 m/s | ||

| Rotating oscillating | 60N/mm2 | Hydrodynamic operation | >2 m/s | |||

| Max. PV dry running | Short-term operation | 3.6N/mm2*m/s | Thermal conductivity | 42W(m*K)-1 | ||

| Continuous operation | 1.8N/mm2*m/s | Coefficient of thermal expansion | 11*10-6*K-1 | |||

| PV max. hydrodynamic | 30N/mm2*m/s | Friction coefficien | Dry | 0.08 ~ 0.20 | ||

| Hydrodynamic | 0.03 ~ 0.08 | |||||

Good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Very good performance in lubricated applications

Good performance in greased applications

Suitable for linear, oscillating and rotating movements

Lead-free material

Standard forms in special dimensions, half-bearings, special shapes obtained by stamping or deep drawing, bearings with locating notches, lubricant holes and machined/stamped grooves, customized bearing designs

Automotive Aerospace, agricultural equipment, construction equipment, pumps and motors, railroad and tramways, textile machinery, valves food and beverage, material handling equipment, forming machines: metal, plastic and rubber; office equipment, medical and scientific equipment, packaging equipment, pneumatic and hydraulic cylinders.