Introducing Inconel self-lubricating bearings – a cutting-edge solution that blends the unmatched strength of Inconel with the efficiency of self-lubrication. These bearings redefine performance standards, offering a wide array of applications across various industries, where reliability, durability, and frictionless operation are paramount. Inconel's remarkable corrosion resistance makes these bearings a top choice for marine environments, chemical processing, and seawater applications. The nickel-chromium alloy offers unparalleled protection against rust and degradation, making the bearings an ideal solution for challenging and aggressive settings.

Defying Extreme Temperatures: High-temperature self-lubricating bearings are designed to operate in environments where temperatures reach far beyond the capabilities of traditional bearings. Whether it's in industrial ovens, kilns, furnaces, or high-temperature manufacturing processes, these bearings thrive where others falter. They maintain their integrity, maintain smooth operation, and continue to provide exceptional performance, even at elevated temperatures.

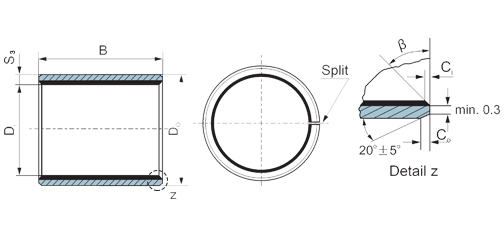

| S3 | CO | Ci | β |

|---|---|---|---|

| 0.75 | 0.5±0.3 | 0.25±0.2 | 30°±5° |

| 1.00 | 0.6±0.3 | 0.30±0.2 | 30°±5° |

| 1.50 | 0.7±0.3 | 0.50±0.3 | 30°±5° |

| S3 | CO | Ci | β |

|---|---|---|---|

| 2.00 | 1.2±0.4 | 0.50±0.3 | 30°±5° |

| 2.50 | 1.8±0.6 | 0.60±0.3 | 45°±5° |

| Unit : mm | |||

| Operating Performance | |

|---|---|

| Dry | Very Good |

| Oil lubricated | Good |

| Grease lubricated | Good |

| Water lubricated | Fair |

| Process fluid lubricated | Good |

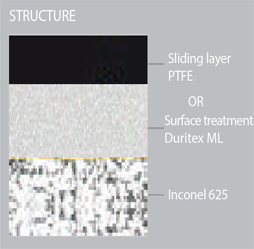

| Structure of the material: | ||

|---|---|---|

| Layer | Average analysis of the material | Thickness of layer |

| Sliding layer (Minimum) |

PTFE Coating | 10 - 30μm |

| OR | OR | |

| Surface treatment | Duritex ML | 0.15 mm (min) |

| Supporting shell | Inconel 625 | 0,50 ÷ 2,70 mm (Depending on Dim. of the Bearing) |

| TECHNICAL DATA | ||||||

|---|---|---|---|---|---|---|

| Max. load | Static | 200N/mm2 | Friction coefficient | 0.07~0.13 | ||

| Very low speed | 100N/mm2 | Max. speed | Dry running | 0.5 m/s | ||

| Rotating oscillating | 60N/mm2 | Hydrodynamic operation | >0.5 m/s | |||

| Max. PV dry running | Short-term operation | 3.6N/mm2*m/s | Thermal conductivity | 42W(m*K)-1 | ||

| Continuous operation | 1.8N/mm2*m/s | Coefficient of thermal expansion | 11*10-6*K-1 | |||

| Temp. limit | -200°c ~ +430°c | |||||

Very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Suitable for lubricated applications

Suitable for very high temperature applications

Standard forms in special dimensions, half bearings half-bearings and customized bearing designs

Industrial: Valves and Isolators Aerospace, agricultural equipment, food and beverage, material handling equipment, forming machines: metal, plastic and rubber; office equipment, medical and scientific equipment, packaging equipment, pneumatic and hydraulic cylinders, pumps and motors, railroad and tramways, textile machinery, construction equipment etc.,

| AXLE | HOUSING H7 | OD Tolerance | ID After fixing | Wall thickness | L0-0.40 (d ≤ 30 L - 0.3d ≥ 30 L - 0.4) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | 40 | 50 | |||||

| 6-0.013-0.028 | 8+0.015 | 8+0.055+0.025 | 6.055 5.990 |

1.005 0.980 |

0606 | 0608 | 0610 | |||||||

| 8-0.013-0.028 | 10+0.015 | 10+0.055+0.025 | 8.055 7.990 |

0806 | 0808 | 0810 | 0812 | 0815 | ||||||

| 10-0.013-0.028 | 12+0.018 | 12+0.065+0.030 | 10.058 9.990 |

1006 | 1008 | 1010 | 1012 | 1015 | 1020 | |||||

| 12-0.016-0.034 | 14+0.018 | 14+0.065+0.030 | 12.058 11.990 |

1206 | 1208 | 1210 | 1212 | 1215 | 1220 | 1225 | ||||

| 13-0.016-0.034 | 15+0.018 | 15+0.065+0.030 | 13.058 12.990 |

1310 | 1320 | |||||||||

| 14-0.016-0.034 | 16+0.018 | 16+0.065+0.030 | 14.058 13.990 |

1410 | 1412 | 1415 | 1420 | 1425 | ||||||

| 15-0.016-0.034 | 17+0.018 | 17+0.065+0.030 | 15.058 14.990 |

1510 | 1512 | 1515 | 1520 | 1525 | ||||||

| 16-0.016-0.034 | 18+0.018 | 18+0.065+0.030 | 16.058 15.990 |

1610 | 1612 | 1615 | 1620 | 1625 | ||||||

| 17-0.016-0.034 | 19+0.021 | 19+0.075+0.035 | 17.061 16.990 |

1.505 1.475 |

1710 | 1712 | 1720 | |||||||

| 18-0.016-0.034 | 20+0.021 | 20+0.075+0.035 | 18.061 17.990 |

1810 | 1812 | 1815 | 1820 | 1825 | ||||||

| 20-0.020-0.041 | 23+0.021 | 23+0.075+0.035 | 20.071 19.990 |

2010 | 2012 | 2015 | 2020 | 2025 | 2030 | |||||

| 22-0.020-0.041 | 25+0.021 | 25+0.075+0.035 | 22.071 21.990 |

2210 | 2212 | 2215 | 2220 | 2225 | 2230 | |||||

| 24-0.020-0.041 | 27+0.021 | 27+0.075+0.035 | 24.071 23.990 |

2415 | 2420 | 2425 | 2430 | |||||||

| 25-0.020-0.041 | 28+0.021 | 28+0.075+0.035 | 25.071 24.990 |

2510 | 2512 | 2515 | 2520 | 2525 | 2530 | 2540 | 2550 | |||

| 28-0.020-0.041 | 32+0.021 | 32+0.085+0.045 | 28.085 27.990 |

2.005 1.970 |

2815 | 2820 | 2825 | 2830 | 2840 | |||||

| 30-0.020-0.041 | 34+0.025 | 34+0.085+0.045 | 30.085 29.990 |

3012 | 3015 | 3020 | 3025 | 3030 | 3040 | |||||

| 32-0.025-0.050 | 36+0.025 | 36+0.085+0.045 | 32.085 31.990 |

3220 | 3230 | 3240 | ||||||||

| 35-0.025-0.050 | 39+0.025 | 39+0.085+0.045 | 35.085 34.990 |

3512 | 3515 | 3520 | 3525 | 3530 | 3540 | 3550 | ||||

| 38-0.025-0.050 | 42+0.025 | 42+0.085+0.045 | 38.085 37.990 |

3815 | 3830 | 3840 | ||||||||

| 40-0.025-0.050 | 44+0.025 | 44+0.085+0.045 | 40.085 39.990 |

4012 | 4020 | 4025 | 4030 | 4040 | 4050 | |||||

| 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 100 | 115 | |||||

| 45-0.025-0.050 | 50+0.025 | 50+0.085+0.045 | 45.105 44.990 |

2.505 2.460 |

4520 | 4525 | 4530 | 4540 | 4550 | |||||

| 50-0.025-0.050 | 55+0.030 | 55+0.100+0.055 | 50.110 49.990 |

5020 | 5030 | 5040 | 5050 | 5060 | ||||||

| 55-0.030-0.060 | 60+0.030 | 60+0.100+0.055 | 55.110 54.990 |

5530 | 5540 | 5550 | 5560 | |||||||

| 60-0.030-0.060 | 65+0.030 | 65+0.100+0.055 | 60.110 59.990 |

6030 | 6040 | 6050 | 6060 | 6070 | ||||||

| 65-0.030-0.060 | 70+0.030 | 70+0.100+0.055 | 65.110 64.990 |

6530 | 6540 | 6550 | 6560 | 6570 | ||||||

| 70-0.030-0.060 | 75+0.030 | 75+0.100+0.055 | 70.110 69.990 |

7040 | 7050 | 7060 | 7070 | 7080 | ||||||

| 75-0.030-0.060 | 80+0.030 | 80+0.100+0.055 | 75.110 74.990 |

7530 | 7540 | 7550 | 7560 | 7570 | 7580 | |||||

| 80-0.030 | 85+0.035 | 85+0.120+0.070 | 80.155 80.020 |

2.490 2.440 |

8040 | 8050 | 8060 | 8070 | 8080 | 80100 | ||||

| 85-0.035 | 90+0.035 | 90+0.120+0.070 | 85.155 85.020 |

8540 | 8560 | 8580 | 85100 | |||||||

| 90-0.035 | 95+0.035 | 95+0.120+0.070 | 90.155 90.020 |

9040 | 9050 | 9060 | 9080 | 90100 | ||||||

| 95-0.035 | 100+0.035 | 100+0.120+0.070 | 95.155 95.020 |

9550 | 9560 | 9580 | 95100 | |||||||

| 100-0.035 | 105+0.035 | 105+0.120+0.070 | 100.155 100.020 |

10050 | 10060 | 10080 | 100115 | |||||||

| 105-0.035 | 110+0.035 | 110+0.120+0.070 | 105.155 105.020 |

10560 | 10580 | 105115 | ||||||||

| 110-0.035 | 115+0.035 | 115+0.120+0.070 | 110.155 110.020 |

11060 | 11080 | 110115 | ||||||||

| 120-0.035 | 125+0.040 | 125+0.170+0.100 | 120.210 120.070 |

2.465 2.415 |

12060 | 12080 | 120100 | |||||||

| 125-0.035 | 130+0.040 | 130+0.170+0.100 | 125.210 125.070 |

12560 | 125100 | 125115 | ||||||||

| 130-0.040 | 135+0.040 | 135+0.170+0.100 | 130.210 130.070 |

13060 | 13080 | 130100 | ||||||||

| 140-0.040 | 145+0.040 | 145+0.170+0.100 | 140.210 140.070 |

14060 | 14080 | 140100 | ||||||||

| 150-0.040 | 155+0.040 | 155+0.170+0.100 | 150.210 150.070 |

15060 | 15080 | 150100 | ||||||||

| 160-0.040 | 165+0.040 | 165+0.170+0.100 | 160.210 160.070 |

16060 | 16080 | 160100 | 160115 | |||||||

| 180-0.040 | 185+0.046 | 185+0.210+0.130 | 180.216 180.070 |

2.465 2.415 |

18080 | 180100 | ||||||||

| 190-0.046 | 195+0.046 | 195+0.210+0.130 | 190.216 190.070 |

19080 | 190100 | |||||||||

| 200-0.046 | 205+0.046 | 205+0.210+0.130 | 200.216 200.070 |

20060 | 20080 | 200100 | ||||||||

| 220-0.046 | 225+0.046 | 225+0.210+0.130 | 220.216 220.070 |

22080 | 220100 | |||||||||

| 250-0.046 | 255+0.052 | 255+0.260+0.170 | 250.222 250.070 |

25080 | 250100 | |||||||||

| 260-0.052 | 265+0.052 | 265+0.260+0.170 | 260.222 260.070 |

2.465 2.415 |

26080 | 260100 | ||||||||

| 280-0.052 | 285+0.052 | 285+0.210+0.130 | 280.222 280.070 |

28080 | 280100 | |||||||||

| 300-0.052 | 305+0.052 | 305+0.210+0.130 | 300.222 300.070 |

30080 | 300100 | |||||||||