Graphite Plugged Bronze Bushings are all self-lubricating and maintenance free. These bushings are machined out of continuous cast bronze and plugged with solid lubricant plugs. The cast bronze base material gives these products stronger bearing abilities. This type of bush is often used in high speed applications where traditional lubricants would not be effective. These bushes an also operate at higher temperatures than traditional bushes. The graphite plugged bronze bushes can reduce sliding friction and provide a longer-lasting, smoother operation for your machinery.

TU-GB material is made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/low temperature with low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent of oscillating motion.

May work without any oil for long period

Extremely high load capacity, good anti-wear and lower friction

Particularly appropriate for low speed an high load

Suitable for reciprocating, oscillation or intermittent motion where oil film is hard to be formed

Good chemical resistant and anti-corrosion characteristics

Can be used in wide range of temperature from -40°C

This kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection molding machines...

| Main Metal Type | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | 650 | 650S5 | 650W1 | 650W3 | 650S1 | 650S2 | 650S3 | |

| Material | CuZn25Al5Mn4 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 | ||||

| Density | 7.8 | 8.9 | 7.8 | 8.9 | ||||

| HB hardness | ≥210 | ≥240 | ≥210 | ≥235 | ≥70 | ≥100 | ≥75 | |

| Tensile strength Mpa | ≥750 | ≥800 | ≥755 | ≥755 | ≥250 | ≥500 | ≥270 | |

| Yeild strength Mpa | ≥450 | ≥450 | ≥400 | ≥400 | ≥90 | ≥260 | ≥150 | |

| Elongation% | ≥12 | ≥8 | ≥12 | ≥12 | ≥13 | ≥10 | ≥5 | |

| Coefficient of linear expansion | 1.9x10-5 / °C | 1.8x10-5 / °C | 1.6x10-5 / °C | 1.8x10-5 / °C | ||||

| Max. temp. | -40~+250℃ | -40~+400℃ | ||||||

| Max. load Mpa | 50 | 75 | 75 | 100 | 50 | |||

| Max. speed m/s | Dry | 0.5 | 0.1 | 0.5 | 0.1 | 0.5 | ||

| Lubrication | 1 | 0.25 | 1 | 0.25 | 2.5 | |||

| Max. PV (N/mm2 *m/s) | Dry | 1.65 | 1 | |||||

| Lubrication | 3.25 | 1.65 | ||||||

The above technical data is recommend from AWWA, better to test under detail condition.

| Solid Lubricants | ||

|---|---|---|

| Lubricant | Features | Typical application |

| SL1 Graphite+add | Excellent resistance against chemical attacks and low friction. Temp limit 400°C | Suite for general machines and under atmosphere |

| SL4 PTFE+MOS2+add | Lower in friction and good for water lubrication, Temp. limit 300°C | Suite for water/sea lubrication, like ship, hydraulic turbine, gas turbine etc. |

Steel shell with cast bronze bearing material liner with specially formulated solid lubricants embedded into the holes in the liner material. The process of casting bronze on steel achieves an integral metallurgical structure between bronze and steel with an increased carrying capacity while the material cost is considerably reduced. The solid lubricant can reduce the coefficient of friction and performs the self-lubricating function.

TU- GB combines the advantages of a metallic bearing and the self lubricating of graphite. It is particularly good for low-speed and high load applications, where external lubrication is not practical. The new based material provides economic solution and even good resistance to shock loads.

| Tech. Data | |||||

|---|---|---|---|---|---|

| Max. load | Static | 250N/mm2 | Temp. | -100℃~+300℃ | |

| Dynamic | 100N/mm2 | Friction coefficient | 0.03~0.20 | ||

| Max. speed | Dry | 0.5m/s | Thermal conductivity | 60W(m*k)-1 | |

| Lubrication | 1.0m/s | Coef. of thermal expansion | 19*10-6K-1 | ||

| Max. PV | 3.25N/mm2*m/s | Interlay bonding strength | 150N/mm2 | ||

| Bronze alloy hardness | HB>210 | ||||

This type of products can be widely used under high temperature and high load with low speed conditions, such as successive casting machinery, mineral machinery, injection molding machinery, dock machinery and so on.

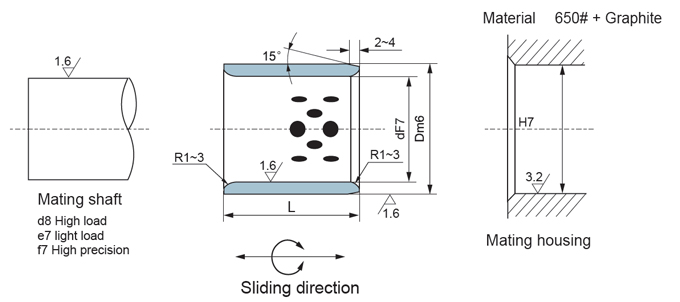

| dF7 | Dm6 | L-0.10-0.30 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | ||||

| 8 |

+0.028+0.013

|

12 |

+0.018+0.007

|

081208 | 081210 | 081212 | 081215 | ||||||||||

| 10 | 14 | 101408 | 101410 | 101412 | 101415 | 101420 | |||||||||||

| 12 |

+0.034+0.016

|

18 | 121810 | 121812 | 121815 | 121816 | 121820 | 121825 | 121830 | ||||||||

| 13 | 19 |

+0.021+0.008

|

131910 | 131915 | 131916 | ||||||||||||

| 14 | 20 | 142010 | 142012 | 142015 | 142020 | 142025 | 142030 | ||||||||||

| 15 | 21 | 152110 | 152112 | 152115 | 152116 | 152120 | 152125 | 152130 | |||||||||

| 16 | 22 | 162210 | 162212 | 162215 | 162216 | 162220 | 162225 | 162230 | 162235 | 162240 | |||||||

| 18 | 24 | 182412 | 182415 | 182416 | 182420 | 182425 | 182430 | 182435 | 182440 | ||||||||

| 20 |

+0.041+0.020

|

28 | 202810 | 202812 | 202815 | 202816 | 202820 | 202825 | 202830 | 202835 | 202840 | 202850 | |||||

| 22 | 32 |

+0.025+0.009

|

223212 | 223215 | 223220 | 223225 | |||||||||||

| 25 | 33 | 253312 | 253315 | 253316 | 253320 | 253325 | 253330 | 253335 | 253340 | 253350 | 253360 | ||||||

| 30 | 38 | 303812 | 303815 | 303820 | 303825 | 303830 | 303835 | 303840 | 303850 | 303860 | |||||||

| 35 |

+0.050+0.025

|

45 | 354520 | 354525 | 354530 | 354535 | 354540 | 354550 | 354560 | ||||||||

| 40 | 50 | 405020 | 405025 | 405030 | 405035 | 405040 | 405050 | 405060 | 405070 | 405080 | |||||||

| 45 | 55 |

+0.030+0.011

|

455530 | 455535 | 455540 | 455550 | 455560 | ||||||||||

| 50 | 60 | 506030 | 506035 | 506040 | 506050 | 506060 | 506070 | 506080 | |||||||||

| dF7 | Dm6 | L-0.10-0.30 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 35 | 40 | 50 | 60 | 70 | 80 | 100 | 120 | 140 | 150 | ||||

| 50 |

+0.050+0.025

|

62 |

+0.030+0.011

|

506230 | 506235 | 506240 | 506250 | 506260 | 506270 | |||||

| 50 | 65 | 506530 | 506540 | 506550 | 506560 | 506570 | 506580 | 5065100 | ||||||

| 55 |

+0.060+0.030

|

70 | 557040 | 557050 | 557060 | 557070 | ||||||||

| 60 | 74 | 607430 | 607435 | 607440 | 607450 | 607460 | 607470 | 607480 | ||||||

| 60 | 75 | 607530 | 607535 | 607540 | 607550 | 607560 | 607570 | 607580 | 6075100 | |||||

| 63 | 75 | 637560 | 637570 | 637580 | ||||||||||

| 65 | 80 | 658050 | 658060 | 658070 | 658080 | |||||||||

| 70 | 85 |

+0.035+0.013

|

708535 | 708540 | 708550 | 708560 | 708570 | 708580 | 7085100 | |||||

| 70 | 90 | 709050 | 709060 | 709070 | 709080 | |||||||||

| 75 | 90 | 759060 | 759070 | 759080 | 7590100 | |||||||||

| 75 | 95 | 759560 | 759570 | 759580 | 7595100 | |||||||||

| 80 | 96 | 809640 | 809650 | 809660 | 809670 | 809680 | 8096100 | 8096120 | ||||||

| 80 | 100 | 8010040 | 8010050 | 8010060 | 8010070 | 8010080 | 80100100 | 80100120 | 80100140 | |||||

| 90 |

+0.071+0.036

|

110 | 9011030 | 9011050 | 9011060 | 9011070 | 9011080 | 90110100 | 90110120 | |||||

| 100 | 120 | 10012060 | 10012070 | 10012080 | 100120100 | 100120120 | 100120140 | |||||||

| 110 | 130 |

+0.040+0.015

|

11013080 | 110130100 | 110130120 | |||||||||

| 120 | 140 | 12014080 | 120140100 | 120140120 | 120140140 | |||||||||

| 125 |

+0.083+0.043

|

145 | 125145100 | 125145120 | 125145140 | |||||||||

| 130 | 150 | 130150100 | 130150120 | 130150140 | ||||||||||

| 140 | 160 | 140160100 | 140160120 | 140160140 | ||||||||||

| 150 | 170 | 150170100 | 150170120 | 150170140 | 150170150 | |||||||||

| 160 | 180 | 160180100 | 160180120 | 160180140 | 160180150 | |||||||||